This extrusion walkthrough shows how PLA colored filament can be produced with the Filament Maker using virgin PLA pellets and masterbatch pellets which contain pigments.

1. General

1.1. Goal

This document shows the extrusion process of PLA with added colorants containing the right settings and some important things to keep in mind when extruding PLA with colorants using the 3devo filament maker. The material Ingeo Biopolymer 3D850 (PLA) is shown in Table 1.

Please note that this document is only an indication on the extrusion process, different machines and grades of PLA and colorants may require different settings.

1.2. Relevant material properties

Table 1: Material name and thermal properties

| Material name | PLA (Polylactic Acid) Ingeo Biopolymer 3D850 |

| Melting range | 165-180°C |

| Max extrusion temperature | 220°C |

| Glass transition temperature | 55-60°C |

1.3. Final extruder settings

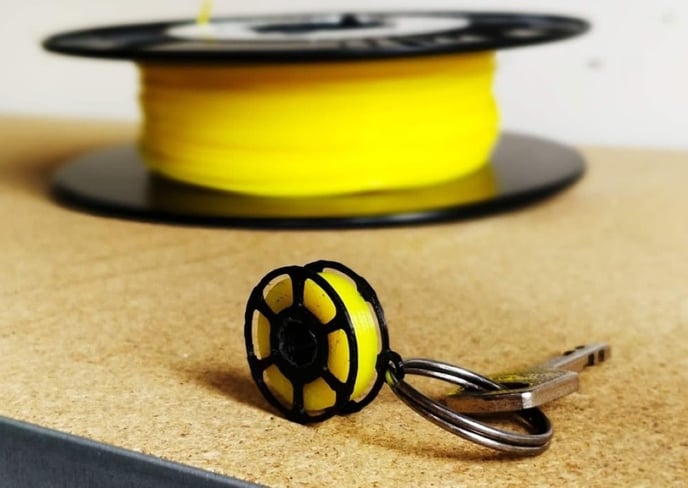

Underneath are the settings shown which needed for the extrusion of PLA with pigments. Table 2 shows the setting needed for the extrusion of filament on 2.85mm, and Table 3 shows the settings needed for the extrusion of filament on 1.75mm. Underneath is also a picture of some made spools using these settings. In front of the spools are also some 3d-prints made from these spools.

Table 2 and 3: The most optimal settings we found to process 2.85mm and 1.75mm filament respectively.

| Extrusion settings (2.85mm) | Heater 4 | Heater 3 | Heater 2 | Heater 1 |

| Heater setpoint (°C) | 170 | 185 | 190 | 180 |

| Screw speed | 5RPM | |||

| Fancooling | 70% (depends on room temperature) |

| Extrusion settings (1.75mm) | Heater 4 | Heater 3 | Heater 2 | Heater 1 |

| Heater setpoint (°C) | 170 | 185 | 190 | 180 |

| Screw speed | 3.5RPM | |||

| Fancooling | 80% (depends on room temperature) |

"Optimal" settings may vary depending on small details (room temperature, drying conditions,...). Especially the fancooling percentage.

2. Preparation

Underneath is an explanation of how the extrusion of PLA with colorants is started. Here is explained which actions should be taken when starting with the extrusion of PLA with colorants. Included is an short explanation of how to clean the machine so that all the colours will be removed out of the machine. In 2.3 is a possible issue and an explanation of how this problem can be solved.

2.1. Starting up the extruder

Before the extrusion of PLA with colorants, pigments should first be mixed with the PLA. 3devo's filament maker has a mixing section at the end of the barrel. Therefore a mix of only 0.5% pigments in PLA is enough for well coloured filament. When mixing the pigment with the PLA, it’s important that all of the pigment are mix so that all of the pigments are very well spread out in the PLA, as shown in Figure 3.

Different colours can be mixed together. The purple PLA shown in Figure 4 is made with a mix of PLA with 0.25% blue pigments and 0.25% red pigments as shown in Figure 5.

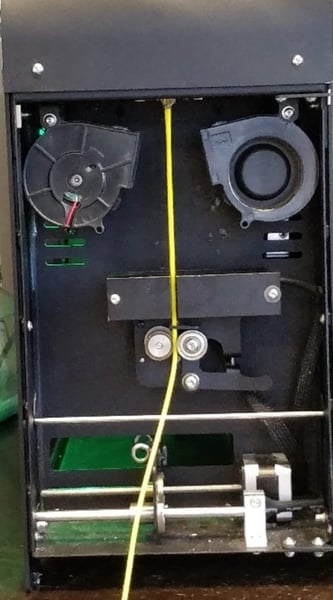

After the pigment are mixed in the PLA, the extrusion can be started. First let normal PLA run, after a couple of seconds the mixed PLA with pigments can be placed in the hopper. Wait for the colour of the filament to turn into a bright colour and start spooling. Figure 2 shows the colourless PLA transitioning into yellow.

2.2. Cleaning the extruder

After the extrusion of PLA with pigments, it’s important to clean the filament maker well enough to get all the colours out of the machine. Pigments can stay in the machine very long when the extruder isn’t cleaned as followed:- Set all heaters to 210°C and wait for all the heaters to reach the set temperature.

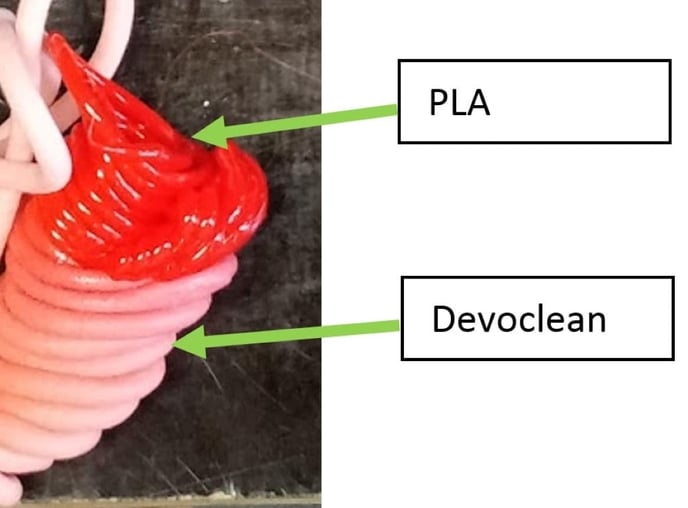

- Let the hopper run almost empty. Fill the hopper with Devoclean Mid-Temperature and wait until Devoclean MidTemp EZ comes out of the nozzle (shown in Figure 6). Make sure the temperatures all reached their set point before filling the hopper with Devoclean MidTemp. When this is not done, there is a change the nozzle will pop out of the machine.

- When Devoclean MidTemp is coming out of the nozzle, the extruder speed should be set to 2 RPM. Wait for +-5 minutes before continuing.

- Set the extruder speed to 13 RPM and again wait for +-5 minutes.

- Repeat step 3 and 4 until the Devoclean MidTemp coming out of the nozzle is pure white (shown in Figure 7). This should probably take around 2 to 4 runs. Devoclean MidTemp can stay in the extruder after extrusion has finished.

2.3. Possible issue and solution

During the extrusion of PLA with pigments, there is one problem which can occurred. This problem is a blob in the filament during the extrusion, as shown in Figure 8. This especially happened during the extrusion with red pigments. The probable solution for this problem lays with the size of the pigment pellets. The pigment pellets, especially the red pigment pellets, are bigger then the PLA pellets. This will probably be the reason of the blobs in the filament. This problem is easily solved by laying the pigment pellets between two small metallic plates and hitting the top plate with a hammer. This will crush the pellets into smaller pieces, solving the problem (shown in Figure 9).

3. Conclusion and recommendation

PLA is very well extrudable into filament when using the standard PLA-settings for 1.75mm and for 2.85mm. The PLA only needs to be mixed with a total of 0.5% pigment for well coloured filament. Different colours can be made by mixing two pigment colours into a total of 0.5%.

After the extrusion of PLA with pigments, it’s important to clean the machine properly with Devoclean Mid-Temperature. There is a small chance blobs form in the filament during the extrusion. This is easily solved by breaking the pigment pellets into smaller pieces. When this is done, perfect coloured filament can be made. Below are close-up views of the filament shown.