The Filament Maker produces abnormal loud squeaky noise

Under certain circumstances, the Filament Maker might start emitting loud squeaky, often metallic, noises. The noise typically becomes cyclic, as the screw spins.

What does it mean?

When the Filament Maker emits a cyclic, loud, squeaky noise, it indicates that the screw is touching the barrel. Beside being quite annoying for the user, this phenomenon often indicates that the Filament Maker is operating sub-optimally, and that the extrusion results are being disturbed. This issue must be fixed before you can achieve good, reliable extrusion results again.

Cause

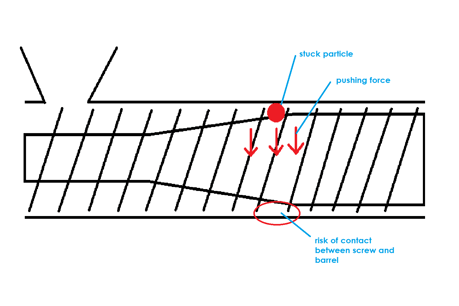

The screw can be misaligned when a particle is too large to travel through the barrel. The minor diameter of the screw increasing along the barrel, in order to apply a compression ratio and build pressure. For that reason, it is possible for particles to enter the barrel, but not necessarily come out. Sometimes, when a particle gets stuck and the pressure is sufficient, said particle can essentially push the screw away from the barrel, resulting in a contact on the other side of the screw.

The following particles can cause this issue :

- Unmelted particles from previous extrusion runs (in case the hopper wasn't empty or the transition was incomplete)

- Partially melted particles

- Debris dropped accidentally in the hopper

- Other contaminants (unpurged residue, degraded/burnt material...)

Please note that a particle can remain stuck for a long time, sometimes disturbing the flow.

Solution

The objective is to free the barrel from the stuck particle. Unless the item is huge and unbreakable (e.g. a metal bolt), you might be able to push it out by purging the Filament Maker.

We recommend a Standard Purge, followed by a Quality Check.

Please also check out our Maintenance Guide.

Contact Support

Lastly, if you have any reservations about carrying out a Purge, the purge was not successful, or you have any additional enquiries, please Contact Support.