Replace the Puller Wheel of the Filament Maker

After using the puller wheel for a while it is possible that the wheel becomes worn, or damaged. This could have an effect on the extrusion results therefore it is time to change the wheel.

When should you replace the puller wheel?

The rubber wheel can be damaged by thermal and mechanical constraints:

- The filament getting stuck during the pulling/spooling process can cause a lot of friction. Look out for the puller wheel slipping (it scrapes away material).

- Excessively hot filament can degrade the polyurethane. In normal cases, the filament is cooled down enough to not degrade the polyurethane.

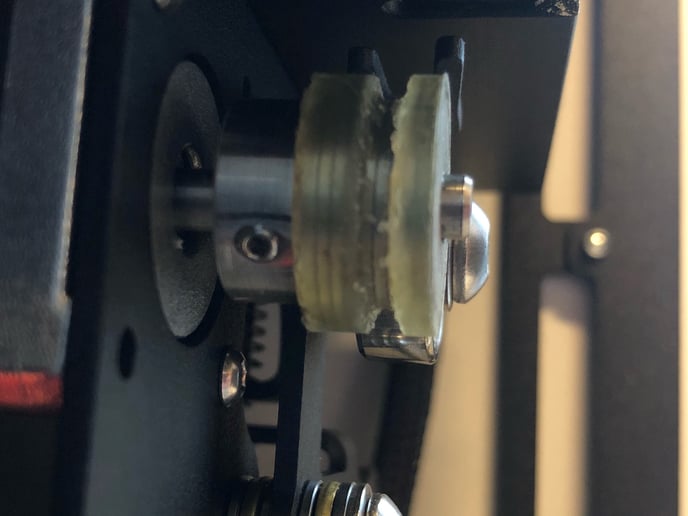

The wheel should be changed when visibly grooved or rough. Below is an extreme example of damage done to the puller wheel.

Before you start

Collect the following items:

|

|

The guide

You will find clear steps on how to remove and replace the puller wheel in the following pdf.

Replacing the Puller Wheel Guide

Note:

Please make sure that the new puller wheel lines up with the metal wheel (bearing) opposite. They should be symmetric so they can accurately grip the filament and pull.

Where to get a new puller wheel?

The fastest way to do this is to directly place an order in our form, by selecting "Purchasing only spare parts / Consumables" in the menu.