How to remove and install the GP20 Granulator rotor

Removing the GP20 Granulator rotor is easy after the filter screen has been removed. This action allows for cleaning and provides access to the Granulator knives.

Tools required

- Cut resistant gloves

- 8mm Allen key

- Loctite 243

Warning

Always wear cut-resistant gloves when working around and inside the cutting chamber.

Instructions

- Open the granulator door, remove the container and remove the filter screen as instructed in this article.

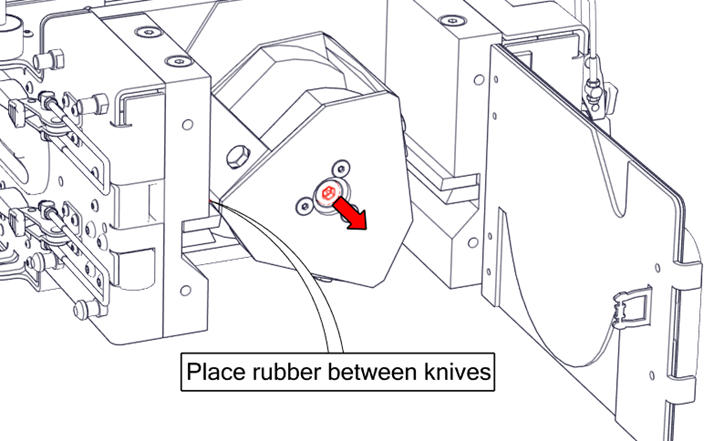

- Block the rotor by placing a piece of rubber between the rotary and stationary knives. Use an 8mm Allen key to unscrew the bolt that locks the rotor in place.

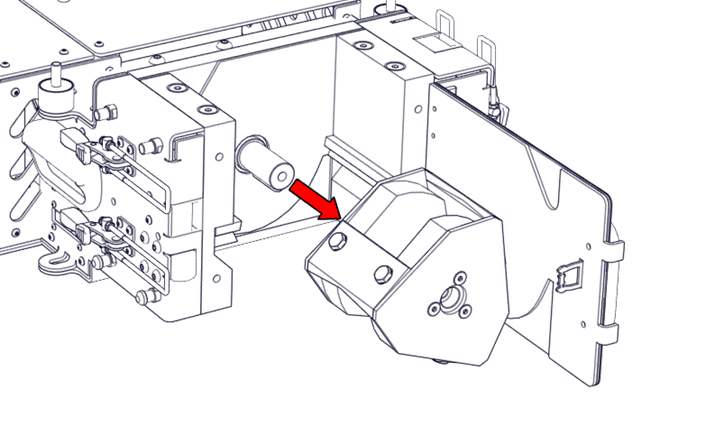

- Carefully slide the rotor out of the cutting chamber.

Note

Ensure you have the Loctite 243 available before removing the rotor from its place. The Loctite has to be re-applied to ensure they remain in place during operation.

|

|

- When installing the rotor, it is important to properly clean the cutting chamber first to ensure proper alignment of the rotor.

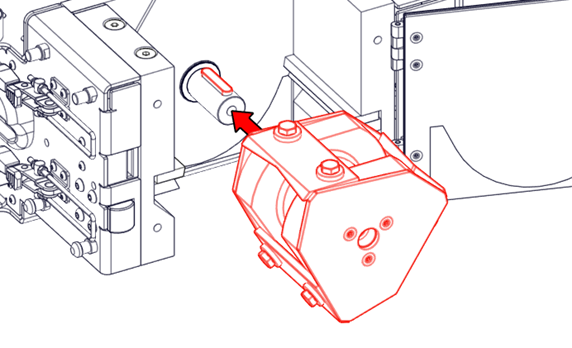

- Locate the keyway inside of the hole of the rotor and locate the key inside of the shaft

|

|

- Slide the rotor fully on the drive shaft

- Apply a fair amount of Loctite 243 to the end of the bolt that goes into the center of the rotor.

Caution

Ensure to not forget to apply the Loctite 243 to the center bolt before reinserting it into the machine. Skipping this step may lead to excessive machine damage.

- After applying the Loctite 243, insert the bolt through the hole in the center of the rotor and tighten it.

- Manually turn the rotor to verify that the rotor runs smoothly.

Caution

Loctite 243 requires a few hours to dry, so during the first 24 hours, you can run the machine empty for a few minutes to ensure it operates perfectly. Avoid operating the machine with materials during this time.