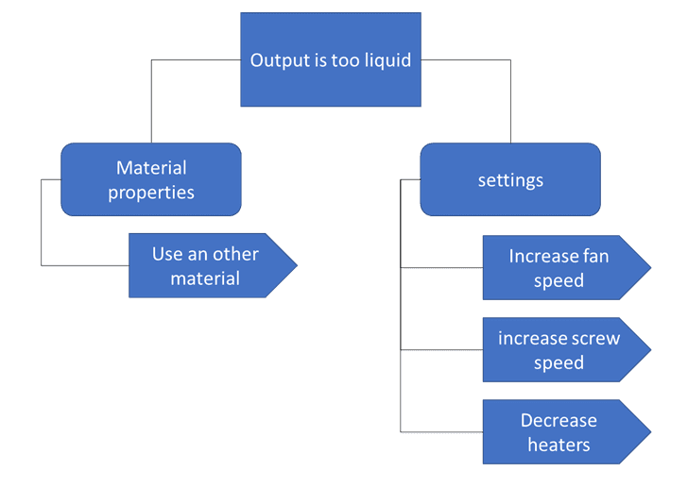

Output is too liquid

The extrusion output can be sometimes too liquid when leaving the nozzle of the Filament Maker. In this article we have a look at the causes and fixes.

Before the filament output can be placed between the puller wheels, it needs to be solid enough. When this is not the case, it is impossible to shape the filament to the desired thickness. How liquid the material is depends on the viscosity of the material. The viscosity is of a material dependent on the material properties and temperature.

1. Material properties

The melt flow index (MFI) can help to compare the viscosity of materials. This property is different for each grade of material. When a material has a high MFI (>15 g/10min), the material has a low viscosity, resulting in a very liquid output. We can't change material properties, so it's best to choose a material with the properties you can use and need. Not sure how to pick the right material? This following article explains the way to determine the suitable material for your purpose:

2. Filament Maker settings

When a material has a suitable MFI, you can increase the viscosity by decreasing the temperature of the material. Of course, the easiest way to cool the material is by increasing the fan speed. But the easiest way isn't always enough. In this case, you can reduce the temperatures of the heaters. By reducing the heaters, the material cools down and therefore increases the viscosity. It is also possible to increase the screw speed, reducing the time the material spends heating. However, by increasing the speed, the friction in the barrel increases what could cause the temperature to rise and not the viscosity.

3. Chart with causes and actions