Output too low or thin

During the extrusion it could occur that the output of material is too low. When this is the case it is not possible to produce filament with the desired thickness. In this article the possible causes and fixes are explained.

When producing filament, it is important that the output of material is enough to create filament for your desired thickness. Unfortunately, sometimes the output is too low and therefore the desired thickness is not reached.There are multiple ways to recognize if the output of material is too thin. The first way to identify this issue is by looking. In most cases, it's enough to tell just by looking; however, it is not always easy to see if the output is too low.

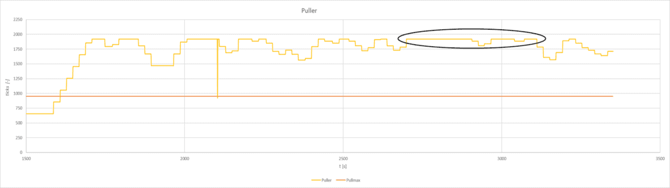

In those cases, Devovison is a helpful tool. When using Devovision, you'll see the speed of puller wheels on display. Figure 1 is an example presented of an output that is too low.

Figure 1: Devovision overview of low output.

Figure 1: Devovision overview of low output.

As visible in figure 1 the display shows the puller wheels are turning at 1920 ticks. This is the lowest speed the wheels can turn. If this is happening, it means that the material output is too low and should be increased.

1. Screw speed

A cause of the low output is that the screw speed is too low. When the screw speed is too low, insufficient material is pushed through, resulting in too low output. By increasing the screw speed, we can solve this issue. When increasing the screw speed, it's worth knowing that the best results are usually achieved with an output between 2rpm and 8rpm. If you find yourself increasing the screw speed above 8rpm, there is a big chance something else is wrong.

2. Feeding issues

Unfortunately, there are also other possible causes for the low output; it can already happen in the feeding section of the Filament maker.

Hopper runs empty

The first and most obvious issue that could cause a low material output is when the hopper runs empty. This way, no new material enters the screw, and no material gets pushed out. Therefore, make sure to properly monitor the amount of material filled in the hopper to keep it full during extrusion.Material isn’t fed

Another reason could be that the material in the hopper isn’t fed into the screw. With no material entering the screw, little gets pushed through, resulting in low output. Different causes could prevent the material from being properly fed into the screw. Cohesive structures When working with regrinds or powders, cohesive structures can form between the material. Different types of cohesive structures can be created in figure 2, you can see the two most common structures.

Figure 2: overview of common cohesive structures

Figure 2: overview of common cohesive structures

Both structures prevent new material from entering the screw and limiting the flow. Therefore, you should look out for these structures during the extrusion to ensure enough material is fed to the screw. In addition, when the cohesive structures form during the extrusion, they must be broken down and prevented from happening again. To break the cohesive structures, the materials inside the hopper must be moving. You can do this by stirring the material; however, this should be a continuous movement to prevent the cohesive structures from forming again. An easier way to make sure this constant movement is happening is by using the feeder. The feeder uses vibratory pulses to ensure a stable flow of material.

Particle size

Another feeding issue that could result in a too low flow is when the materials have a particle size that is too big. For example, we designed our Filament Makers for particles with a diameter of 4mm. So, when larger particles enter the hopper, they won't get fed into the screw because of their size. It can be helpful to sieve the material through a sieve with 4mm holes; this way, particles that are too large can be sorted away or made smaller by shredding.

3. Melting issues

The final issues that could result in a limited flow are melting issues. When the material doesn’t melt or melts too early, this can cause problems with the amount of output. Material melting too early When a material melts too early, less pressure is built up inside the barrel. The pressure build-up is essential to create a good filament. Therefore, when the material melts too early, you should reduce the temperatures of the first heaters. The result is that the material will melt further down the barrel, resulting in a better pressure build-up and, therefore, a proper output Material doesn’t melt properly When the temperatures of the Filament maker are not high enough, the material in the screw might not fully melt, limiting the flow of material. The temperatures of the heaters should be increased to solve this. By increasing the heat, the materials will fully melt, therefore creating a proper flow of material.

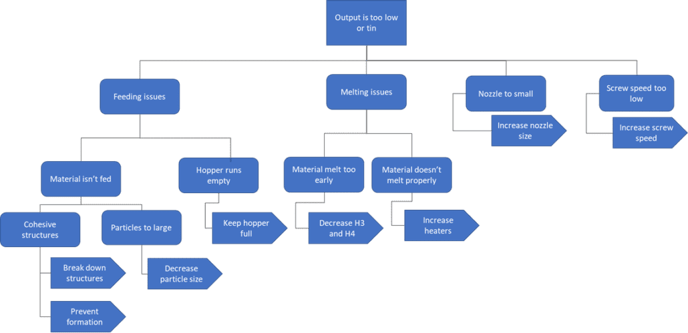

4. Chart with causes and actions

Figure 3 shows a summary of the possible causes and the corrective actions that should be taken when the output of material is too low or tin.

Figure 2: Summary of potential causes and corrective actions when output is too low or tin.