Bumps or particles in filament

When processing material on the filament maker it could be possible the filament contains small bumps. In this article is described what could cause this particles and how you can fix them.

Sometimes filament that is produced with the Filament Maker contains bumps and particles an example of this is presented in figure 1.

Figure 1: Degraded polymer compared to the nondegraded polymer

Figure 1: Degraded polymer compared to the nondegraded polymer

1. Unmolten particles

The first reason for unmelted particles is that the polymer you have chosen to extrude is contaminated with another polymer with a higher melting temperature. This higher melting temperature causes the unwanted polymer not to melt, resulting in bumps. To avoid this, ensure that there are no unwanted contaminants in the batch of polymer you would like extruded.

Another possibility for the bumps is that the desired polymer is not melting correctly. Firstly you can try increasing the temperatures of the heaters; this results in the melting of the polymer and therefore removes the bumps from the filament. Another option is to reduce the screw speed; this increases the polymer's time in the barrel, giving it more time to melt.

In some rare cases, it might be necessary to reduce the temperatures of the heaters, creating a more homogeneous melting. The reduction of the temperatures usually only works when working with amorphous polymers. Because the decrease in temperatures only works in some rare cases, we would recommend starting with increasing the temperatures and only when this does not work, reduce the temperatures.

2. Nozzle build-up

It is also possible that a form of nozzle build-up causes bumps or particles in the filament. Nozzle build-up occurs when the polymer starts to solidify in the nozzle. In some cases, the solidified polymer is pulled down by the unmolten polymer causing a bump in the filament. The following article describes what causes nozzle build-up and how you can solve it.

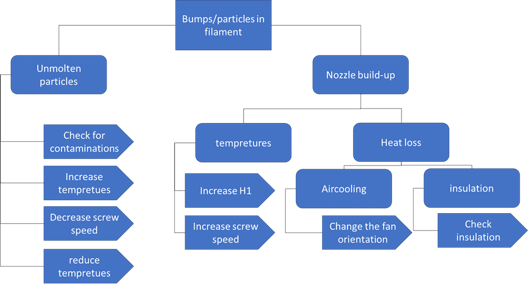

3. Chart with causes and actions Figure 2 shows a summary of the possible causes and the corrective actions that should be taken when the produced filament contains bumps.

Figure 2: Summary of potential causes and corrective actions when filament contains unmolten particles.

Figure 2: Summary of potential causes and corrective actions when filament contains unmolten particles.