PP (polypropylene) extrusion tips

PP is highly crystalline. That can be a problem. Its high crystallization rate can cause the filament to deform, just like how a 3d print could warp.

1. Crystallization ?

PP contains two microstructures at the same time:

- an amorphous fraction --> let's call this 'normal plastic'

- a crystalline fraction --> it is more compact and cohesive than amorphous plastic

When it comes out of the nozzle, fully melted, all its crystals have already melted into an amorphous matter. At this stage, all the matter is typically transparent. Upon cooling down, a fraction of its structure becomes crystalline. Doing so, this fraction becomes opaque. But most importantly it shrinks more than the amorphous fraction. The slower the cooldown step, the more time the matter has to crystallize, and therefore the more it shrinks.

2. Cooling problem

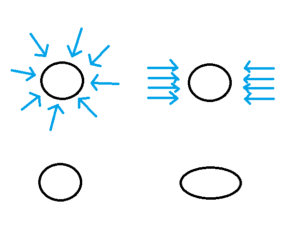

The problem here is that the cooling is done by two fans, one on each side. The cooling can therefore be considered ‘directional’, the air not being blown from all directions around the filament.

This is normally not an issue. However, with highly crystalline polymers like HDPE and PP, this means trouble.

What happens is that one direction of the cross-section is being cooled down faster than the other directions. The directions of the cross-section cool down at different rates, crystallize more/less, and shrink differently.

The resulting filament becomes oval and deformed, as opposed to round.

3. Another problem looks similar

3. Another problem looks similar

There is another potential cause of ovality, which affects all polymers. If the filament is too hot and soft when reaching the pulling wheels, it can get squished flat/oval in compression. It is important to differentiate the two situations :

- if the filament is oval above the puller already, this is most likely a crystallization problem

- if the filament is oval below the puller but round above it, it just means the filament was squished

4. Possible solutions

It is sometimes impossible to fix the ovality completely. This does not necessarily mean that the filament cannot be printed.

- In general, limiting the need for fancooling is a good strategy: lowering the temperatures (especially H1) and the screw speed will result in a colder, slower output. We often start the extrusion test at 190°C, but end up decreasing down to 170°C approx.

- It is possible, to a certain extent, to convert the directional fancooling into a circular airflow. We tested an imperfect but promising prototype