Waving/Curling filament

Sometimes during the extrusion it might happen the filament will start curling between the nozzle and the IR sensor. The result of this is that the puller wheels will not adjust speed resulting in a filament with a wrong diameter.

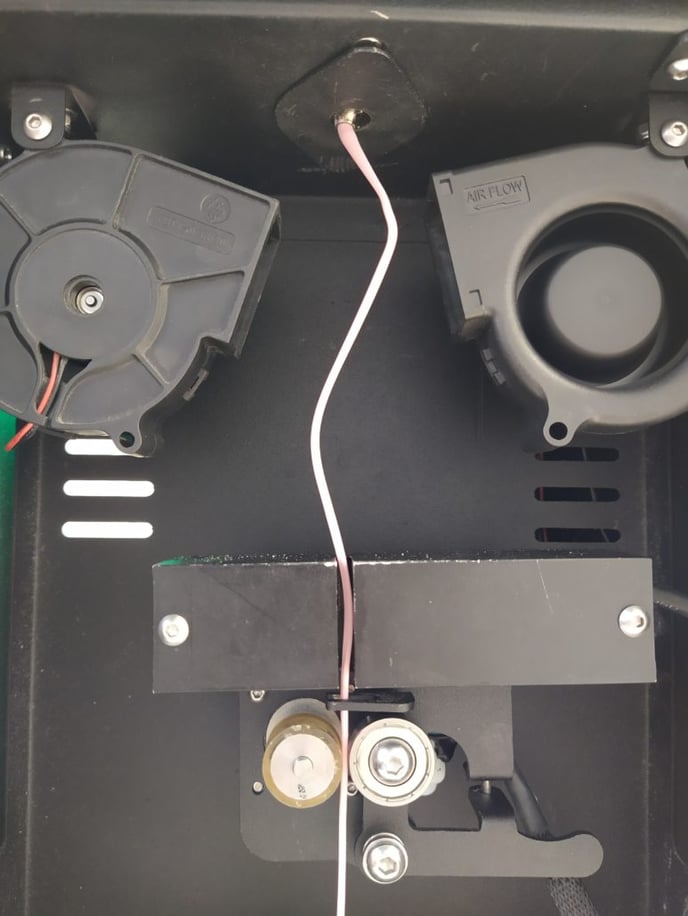

When processing filament on the filament maker it is important the filament will go in a straight line from the nozzle to the IR sensor. This causes the most accurate measurements of the filament thickness. Unfortunately, it could occur that the filament starts waving between the nozzle this phenomena is presented in figure 1.

Figure 1: Example of waving filament

Figure 1: Example of waving filament

1. Output speed

When the output from the nozzle is faster than the amount of filament moved by the puller wheels, the material will start to accumulate between the nozzle and the IR sensor. This accumulation is visible because the filament will begin waving. Because of the waving, the IR sensor will not measure the filament diameter. Therefore, the puller wheel speed will not adjust and fix the accumulation automatically. Instead, you will need to do so manually in the speed setting menu on the filament maker. Next, increase the speed of the puller wheel until the filament flows straight from the nozzle past the IR sensor. Once this happens, you can set the puller speed to automatic once again.

2. Excessive fan speed

When the fan speed is too high, it can cause the filament to start waving. You can minimize the risk of this happening by reducing the fan speed. On the other hand, reducing the fan speed can cause the filament to become flat as described in the following article.

When the fan speed needs to be reduced to prevent the filament from waving. You will need to reduce the temperature of heater 1. This causes the temperature of the material reduce and therefore requires less cooling to prevent it from becoming oval.

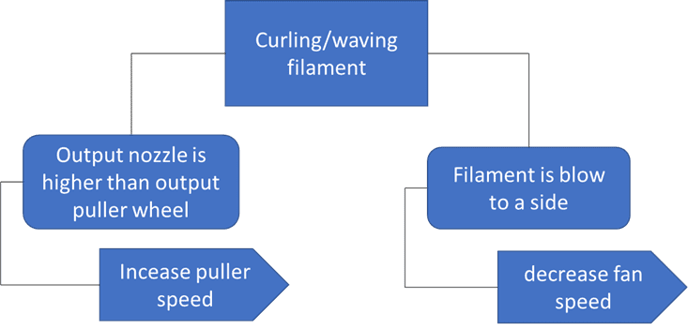

3. Chart with causes and actions

Figure 2 shows a summary of the possible causes and the corrective actions that should be taken when the filament is waving between the nozzle and the IR sensor.

Figure 2: Summary of potential causes and corrective actions when filament is waving.

Figure 2: Summary of potential causes and corrective actions when filament is waving.