Disco Purge

Disco purge is a method of purging where the extruder's RPM is frequently changed during the purging process. This article is a quick and straight-forward explanation to the theory and method of disco purging.

Article Overview:

Theory

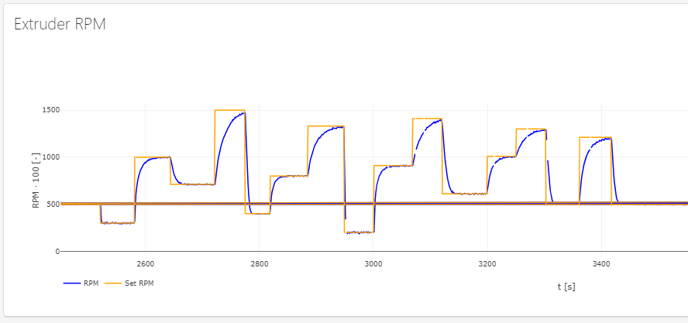

A disco purge is a method of purging where you change the extruder’s RPM very frequently during the purging process. The extruder’s screw speed can be changed every minute, ranging from 2 RPM to 15 RPM.

A mechanical purge benefits from high turbulence and agitation caused by a high screw RPM. But a so called “disco purge” provides a highly fluctuating environment of pressure and agitation that allows a purging compound to work its best.

RPMs

At lower RPMs, the polymer that is adhered to the metal of the extruder or stuck in a corner has a chance to bond with material that is in the mainstream of the barrel and screw.

At higher RPM’s, the velocity of the material on the walls of the barrel is higher and more of the polymer on the walls can be pushed out.

Method

The specific RPM values and times are not necessarily important.

What is important is disrupting the flow patterns and establishing new velocities and shear rates.

One minute at each RPM is sufficient to do this.

For example:

Experiment

It is recommended to experiment with these RPM values to go through the full range of speeds for the screw. However it might differ based on what material you are purging.

Lastly, this cycle might need to be repeated a few times before the extruder is clean.

When to use

Disco purge is an incredibly useful method. Since it requires very little extra time, effort or material, it can be used easily during every single time the machine is purged.

Make sure to familiarize yourself with the ins and outs of purging and maintenance with these articles: