What is Purging?

This article describes the theory behind purging and why it is necessary.

Note:

In essence, this page outlines the theory.

For the practice, head to Purging Your Filament Maker. It will contain practical information, step by step guides, and references to what materials to use, and when.

Definition

Purging is the technical term for cleaning the inside of your extruder’s screw, barrel and nozzle, by extruding a certain “purging material”. This material pushes the residue of the previously used polymer and cleans the inside of the machine, ready to be used again later.

Reason

All the material which was processed and that still remains inside the barrel must be flushed out with a purging material to avoid polymer degradation, resin accumulation, and upkeep the machine's health.

Warning!

Skipping purging can have terrible consequences for the materials and the equipment.

Polymer Degradation

Polymer degradation is the change in the properties of a polymer under the influence of environmental factors such as heat, oxygen, light or chemicals. For the extruder machine, heat is the most common factor. If the polymer is left in the machine after use, it can cause the material’s polymer chains to break down, which is known as a form of degradation.

An example:

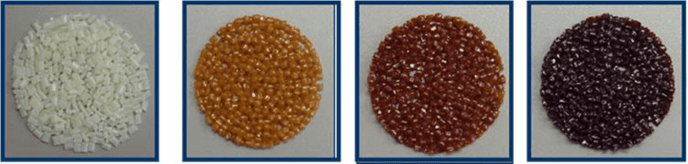

After ABS (acrylonitrile-butadiene-styrene) has been extruded, but it is left in the machine without purging it, degradation will occur. This is because the machine is still hot and cools down very slowly. The images below show how ABS can degrade over time when left in a still hot extruder of around 240°C. The second picture shows discoloration that can occur only after 30 minutes.

Figure 1: Degradation of ABS (ptonline, 2018)

Figure 1: Degradation of ABS (ptonline, 2018)

Polymer degradation also means that the degraded material will not show its original properties and extrusion behavior. Meaning it cannot be used in the next extrusion run. Some particles might not melt, or not melt at the same temperature causing the flow of material to get obstructed or clogged.

These parts can often only be removed by extruding a special purging material, or in worst case scenario, by removing the entire screw.

Resin Accumulation

When the extruder's barrel and screw is not purged properly after use, resin can accumulate. This also causes the flow of material to stagnate and contaminate your filament. The accumulation of old material sticks to the extruders’ screw, and blocks the flow of new material. As a result, polymer degradation will occur because the material’s residence time is too long.

Machine Health

Degraded material can cause build up. Build up can cause extra pressure and stress on the machine parts. Not purging after each and every extrusion run will therefore affect the polymers being used, future extrusion experiments, and the health of the machine, too.

Warning!

In extreme scenarios, the screw can become irreversibly stuck.

For example:

If PEEK or PVA is left in the barrel without flowing (for 5-10min), they can clog the machine entirely and irreversibly. This should be avoided at all cost.

Theory

Purging an extruder’s screw can be divided into two different methods: ‘Chemical Purge’ which makes use of a chemical reaction to break down the material inside the extruder; and the ‘Mechanical Purge'.

Mechanical Purging

The more common and recommended method of purging is the mechanical purging. It makes use of physical force in the form of shear stress which depends on the extruder’s screw speed (RPM) and the differences in material melt viscosity.

- shear stress is external force acting parallel to the flow direction

- melt viscosity is an indication of how “not-liquid” the molten polymer is

(the lower the viscosity, the more liquid it is)

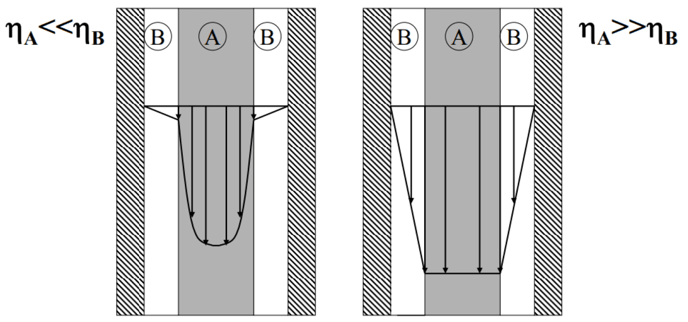

During extrusion of the purging material, the shear stress scrapes/tears the old material from the inside of the extruder’s barrel and along the screw, while the higher viscosity of the purging material pushes everything out. The higher the melt viscosity, the higher the possible occurring shear stress.

These stresses are visualized in Figure 2 in a simplified sketch of the flow of material through the barrel.

Figure 2: Visualization of stresses during purging the extruder, related to material viscosity

Figure 2: Visualization of stresses during purging the extruder, related to material viscosity

η stands for viscosity

letter A for the purging material

letter B for the old/ to be purged material

Note:

Commercial purging materials such as DevoClean also rely on material affinity – they are attracted to carbon (carbon is the product of burnt polymer) and other residue. Find out more about DevoClean Purge on our shop (only available in the Schengen region).

Once again, for the practical applications of this theory, familiarize yourself with the ins and outs of purging: Purging your Filament Maker

the types of purging: Standard Purge and Heavy Purge

and an extra method of purging: Disco Purge

Lastly, check out our Maintenance Guide to be 100% safe with your valuable Filament Maker.