FM Essentials: Material Selection

Choosing the right polymer is essential. Below you will find important tips on how to select and decide on your material. This is the very first step when starting your extrusion journey with the Filament Maker.

Table of Contents

Why is it essential?

The Right Focus

Grade and MFI

Advanced Materials

Conclusion

Further Information

Why is it Essential?

We make filament to print.

Therefore it is quite natural that the success of your 3D print depends on a number of factors that contribute to that process:

- 3D Printer

With this comes the correct printing settings and conditions. - Filament Quality

This is determined by choosing the right material and the extrusion process.

The Right Focus

What is the end result?

Before choosing your material it is crucial that you define the focus precisely. Perhaps you need a material that will make your 3D print chemically resistant in its application. Or it needs to have the right aesthetics, be it color, gloss, or shade. Maybe you are printing items that must have quality engineering properties. Understanding these needs narrows down and focuses your material selection.

And if there are several materials that tick the boxes for you, it would be wise to choose the one that is the easiest to process.

Example 1

You need a material with high mechanical and temperature resistances.

PEEK is a popular option, but PEKK, and PEI are, too. Even with PEEK you have to be aware of the many different grades, as some will be easier to extrude than others.

Example 2

Your project goal is to experiment with additive copper.

PLA is considerably easier to process than most polymers, like PP for example, and PLA works well with additives, too.

Grade and MFI

Here we can start to narrow down our search for the right material through two important terms:

1. Grade

The grade of a polymer corresponds to one specific polymer by a single manufacturer. Normally, each individual grade is associated to and comes with a precise technical datasheet (TDS). Every grade is unique, but we can classify them into big families of grades.

For instance, Acrylonitrile Butadiene Styrene is a family of hundreds of grades of ABS-s.

Another good example is the Ingeo Biopolymer 4043D (polymer) by NatureWorks (manufacturer). A quick Google search will reveal that it is in fact a grade of PLA with its corresponding TDS in an freely available pdf.

2. MFI

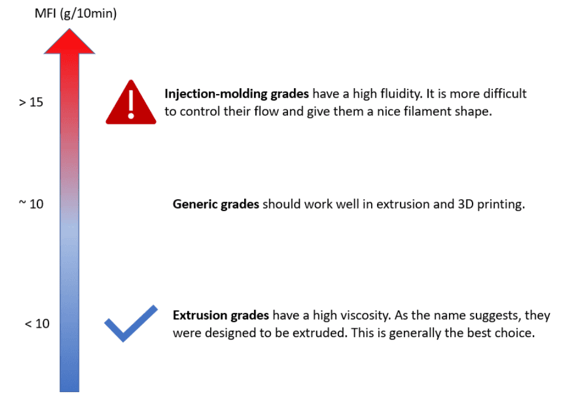

The main difference between these grades is the flowing behavior of the molten polymer. This is quantified by one simple viscosity indicator: Melt Flow Index.

The Melt Flow Index rate is found by measuring what mass of molten polymer can be pushed through a hole (under standardized conditions). MFI is measured in g/10min.

The higher the MFI, the more fluid the plastic is, therefore the lower its viscosity. Below is a simple graph to give you an estimation for MFI values.

This scale is a general indication to help you choose your first material if you have the option to choose, but it does not mean that only extrusion grades can be processed with the Filament Maker. At 3devo, we have successfully processed many injection grades.

Manufactured items typically do not have TDS-s. In that case, the MFI is unknown.

Advanced Materials

Understanding that polymers come in a variety of grades and with different MFIs, it is easy to see how not all materials have the same processability. This also means they cannot be extruded using the same settings. Some require high temperatures and some require additional material knowledge.

Being able to successfully extrude comes with experience and practice, therefore we highly recommend knowing your essentials and practicing on the Filament Maker with easily processable polymers, first.

Examples of difficulties associated with advanced materials:

High-Temperature polymers (PEEK, PEI) can permanently clog the machine!

Highly Crystalline polymers (HDPE, PP) will not solidify uniformly.

Advanced materials require advanced extrusion techniques!

It is crucial to learn and know about these techniques to avoid unsafe practices or irreparable damage!

Introducing more parameters means that there is more to know and more to keep track of. Unfortunately, it also means more things can go wrong, but once successfully the results are invaluable!

Recycling

Typically, recycling plastic comes with more challenges than processing virgin plastics.

This is due to the added steps involved: collecting and sorting parts, shredding, maintaining the cleanliness of the batch. Most annoyingly, there is usually no datasheet available. Please, don’t let this stop you!

We successfully extruded recycled plastic time and time again, and have learned that it works well when all the different parameters are controlled.

Composites (Additives)

To make a composite, the additive or filler must be dispersed throughout the polymer matrix (the base material you are using). There are two options:

- Pre-compounding

This means the additive and the polymer are turned into homogeneous pellets. This is typically achieved via twin-screw extrusion, then turning them into a filament.

This method generally allows you to achieve higher additive proportions.

- Hopper Feeding

This means feeding the polymer and additive together in the Hopper. This is basically combining the mixing and filament making steps at the same time.

However, the risk of clogging the extruder is higher.

Please look into our many additional articles and resources.

- Percentages

When experimenting it is always wise to start with small additive percentages.

This is typically 5%wt (or percentage by weight) and increase that proportion gradually. - Particle Size

This is critical. For us additive particle sizes around 100microns have proven to work very well.

Conclusion

To summarize, choosing the right material makes reaching your goal more effortless. Following a safe, systematic procedure will allow you to quickly assess the processability of a given grade, and perhaps choose another one, if needed.

Lastly, even though some of these points may look like limitations and restrictions, the guidelines correspond to opportunities and discoveries.

At 3devo, we are constantly learning about new processing tricks and will keep updating our resources regularly to share our insights with everyone who is curious to learn more.

Further Information

Find out more about recycling starting with our in house blend PLA.

Advanced material knowledge about additives: Vol 1 and Vol 2.

Our openly available series of Extrusion Reports.

Next essential: The Hopper