Filament Maker Error Messages

During the extrusion process an error message may appear on the display of the Filament Maker. This article explains what could cause the error message and how to prevent it from happening.

Error Messages

"The external supply voltage is too low or absent"

"Extruder motor current limit reached"

"Positioner endstop hit unexpectedly"

"Hopper is empty for too long"

More difficult issues:

"Failure reading a thermocouple"

"Extruder motor thermistor is not connected"

"Extruder motor or encoder error"

"The external supply voltage is too low or absent"

This error occurs when only the USB-cable is connected to the filament maker. To fix this make sure that the power cable is inserted, and the power button (on the back) is switched on.

"Reset signal receiver"

This message is shown when the Filament maker is connected to the DevoVision app on the computer. The connection will trigger a reset that is necessary to update the firmware and result in a connection between the Filament Maker and DevoVision.

"Extruder motor too hot"

This error occurs when the temperature of the extruder is too high.

When the screw generates friction for a long time, the temperature of the motor increases. The friction typically occurs when the screw is working hard to push the material through the filament maker and results in the motor running harder to help the screw. You can reduce the friction by increasing the heater temperatures, so the material in the barrel becomes less viscous and easier for the screw to push along.

"Extruder motor current limit reached"

When the motor current reaches above 9000mA, the Filament Maker turns off. There are two reasons why this error happens:

- An object in the hopper obstructing the screw from rotating.

- The barrel is fully clogged, or the material is not melting correctly. In this case, increase the temperature of the heaters by 20*C, and reduce the screw speed to 2 RPM. For more information, please read the article about the screw NOT rotating.

"Positioner endstop hit unexpectedly"

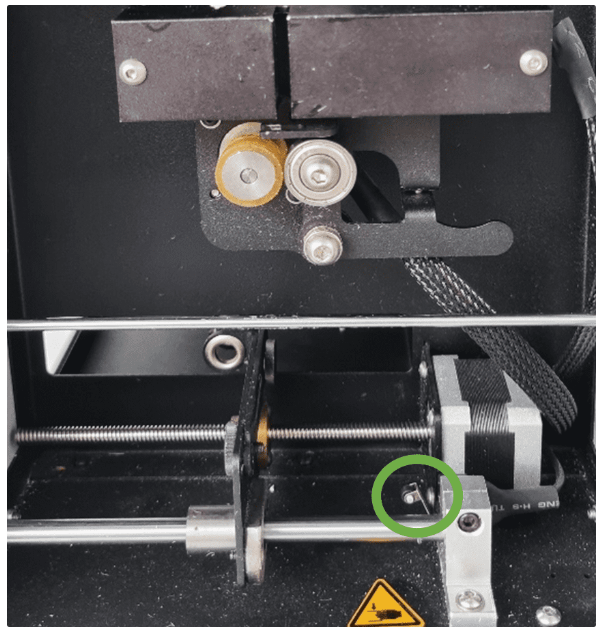

The positioner travels left and right on a threaded rod. An endstop button is placed on the right end of this path. It is possible for an item (filament, tool, etc) to get stuck between the positioner and the endstop button, essentially pressing the endstop button. This triggers the Filament Maker to switch off displaying the error message.

After a reboot, once the obstacle has been removed from the positioner path, the issue should be prevented from reoccurring. Here is the positioner (green circle):

"Hopper is empty for too long"

When the hopper sensor does not measure enough material for 10 minutes, it will turn off the Filament Maker. After the reboot, you can continue the process. Fill the hopper regularly to prevent the Filament Maker from running when empty, thus preventing the filament maker from turning off. It is possible to disable this automatic switch-off : Main menu/Settings/[scroll down]/Hopper empty check/OFF.

Whether you deactivate the hopper empty check or not, we strongly advise you to keep your hopper full of material as long as an extrusion is running. The hopper should only be left empty for less than a minute when transitioning from one material to another.

More difficult issues:

"Failure reading a thermocouple"

This issue is more severe. Please check out its dedicated article.

"Motor current too high"

This issue is more severe. Please check out its dedicated article.

"Extruder motor thermistor is not connected"

This issue is more severe. Please check out its dedicated article.

"Extruder motor or encoder error"

This issue is more severe. Please check out its dedicated article.

None. Permanent Black Screen

This issue is more severe. Please check out its dedicated article.