"Extruder motor or encoder error"

There are multiple possible causes for this error message on your Filament Maker. These causes are described in this article along with how to act accordingly and hopefully fix the issue.

Article Overview

Problem with the encoder(disk)

What it means

It might happen that you are facing the following error message on the display of your Filament Maker, along with it shutting off: "Extruder motor or encoder error".

Simply put, the error refers to the extruder screw not being able to rotate anymore.

Caution

In case you are currently extruding a high-performance polymer, it is very important to act quickly, and not let the material harden inside the extruder, but remove it as soon as possible.

For example, if you are extruding PEEK, this error shows up, and you do not know what to do, it would even be a smart move to call our office and ask our service department directly.

1. Temperatures are too low

Possible cause

The first and most obvious cause for the error message is the extrusion temperature. In order for the extruder screw to be able to rotate consistently and produce an output, the material inside must completely melt. If the material is not completely molten, the screw is stuck and the error message will be displayed.

Possible solution

Please check the technical datasheet of your material or consult the supplier to find out what temperatures the material should be processed at. In all cases, the material has to reach temperatures above its melting point, but sometimes you might have to increase it even more well above this point - you could try increasing the temperatures with steps of 10 or 20℃, and try turning the machine on again.

Caution

Please be careful not to increase the temperatures too much, or have the material inside the extruder for too long at these high temperatures. The material can degrade inside and removing this from the system can be quite difficult.

2. Problem with the encoder(disk)

Possible cause

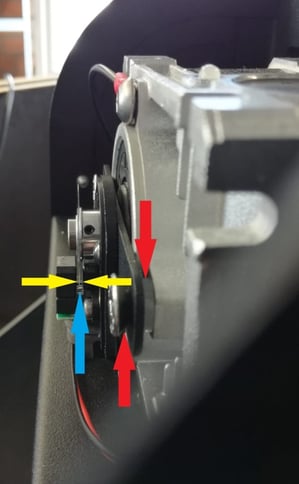

The encoder is a small disk that is attached to the screw and gearbox and rotates along with it. A sensor can detect how fast the encoder is rotating, and with its help the machine can see if the screw is rotating at the correct/set RPM. If this disk is somehow damaged or misaligned, the reading is not accurate anymore, and the machine shows the error on the display.

Possible solution

By clicking the Encoder replacement manual, you can find a manual on how to access the encoder:

Once you have opened up the machine, you can check if the encoder disk is still intact and aligned

Encoder alignment

3. Problem with the motor

Other solutions

If the encoder disk is still intact and aligned perfectly in the middle, it is a good idea to install a diagnostic test firmware on your Filament Maker. With this firmware, the exact issue can be analyzed, and we can find out what is causing the "Extruder motor or encoder error". For this you would need to of course install the firmware, which can be downloaded here: Diagnostic Firmware

This zip file contains the

- diagnostic firmware (FeFirmware-v1.3.1-diag.hex)

- the 3devoUpdate tool, which is used to upload the firmware to the Filament Maker

- and a PDF that explains how to perform the diagnostic test

When the FeFirmware-v1.3.1-diag.hex is installed on your Filament Maker, you can press the menu on "Start diagnose".

Note:

Always make sure that the Arduino program is running and connected to the Filament Maker in able to create and save the log file from this diagnosis. Which you should attach to a support ticket and we can analyze the results.

4. Extruder is clogged

Other issues

If you are working with a high-performance polymer, or a lot of additives (carbon fibers, for example) the risk of clogging the extruder is considerably higher. In this case, you might get the error message "Extruder motor or encoder error", or "Extruder motor current too high", or you might get no output from the extruder anymore.

Caution

When using these types of materials, it is strongly advised to remove the material as soon as possible from the extrusion mechanism, by purging it.

This can prevent having to send the machine back to 3devo for repairs or having to remove the extruder screw. If it is difficult to purge the machine clean from this material because this message keeps coming up, you could try the following things:

- Increase the temperature of Heater 1 (usually 20℃ should be enough).

- Remove the nozzle to relieve some pressure, and let the material flow out more easily.

- Set the screw speed to 15 RPM, to generate some more pressure and force out the clog.

- Use a rectangular-ended wooden stick to push down on the material into the hopper, helping add extra pressure and forcing the extrusion. For this you will have to remove the two bolts closest to the hopper, to be able to slide out the grid/mesh, so you can access the opening of the extruder.

As always, please ensure that you take plenty of safety measures, and do plenty of troubleshooting before attempting one of the more difficult problem-solving methods.

Contact Support if you need any further assistance.