FM Essentials: The Fans

The article that details the information regarding the filament cooling fans on the Filament Maker. These essentials are to help you understand how best to use the machine to your specifications.

The Filament Maker extrudes with a collection of features and components working together efficiently. It is up to the user to utilize these tools and ensure that the machine works well.

Table of contents

Function

Features

Things to Watch Out For

Machine Settings

Safety / Error Messages

Further Information

FunctionAlso known as the Filament Fans or Cooling Fans (there are other system cooling fans inside the Filament Maker). Simply put, their job is to solidify the filament before it gets to the Puller Wheels. The associated action and term is cooling. FeaturesThe fans are a somewhat straight-forward hardware with two variables. The two features are: the strength, or the set percentages, and the angle of the Fans. Though incredibly useful to allow for good extrusion, the Fans are one part of the whole system and should work in tandem with all the other essential components. |

|

Things to Watch out for

These are the most common tips to suggestions that come up in relation to the Fans.

During Transitioning / Purging

- The Fans should be OFF and turned away from the extruding material during a purge or transitioning to the new material.

During Finetuning

- As discussed in Nozzle Essentials, the angle of the Fans must be turned away from the nozzle to avoid clogging.

- Fan cooling percentages, or the strength settings, should come after heating

- When finetuning, it is not recommended to have the final settings of the Fans at 100% cooling. This gives very little flexibility for repeated extrusion results and reoccurring experiments.

- The Fans should be pointing at the filament symmetrically. If the cold air is hitting the filament asymmetrically, it will cause winding and waving and will make it difficult for the sensor to take measurements. This is crucial for highly crystalline materials such as HDPE, or PP, as they might even solidify at a different point on each side of the filament.

Correct Position

Figure 1 showing the correct fan positioning:

- attached cover plate

- symmetric positioning

- fans are pointing towards the flow of the output

Figure 1

Figure 1

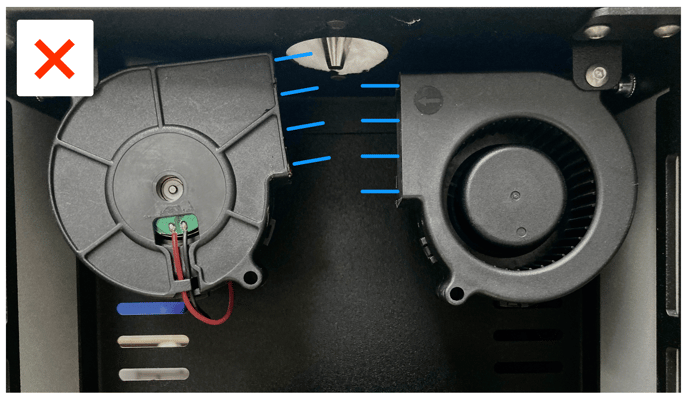

Figure 2 showing an incorrect fan positioning:

- missing cover plate -> might cause more nozzle cooling

- not symmetric -> might cause filament waving

- fans are pointing upwards and/or towards the nozzle -> might cause additional nozzle cooling

Figure 2

Figure 2

Machine Settings

Fan Cooling: 0 – 100%

Safety / Error Messages

Safety Warnings:

The Fans themselves do not pose any danger.

Caution!

Never use the Fans to blast air on output that is very liquid!

When the output is extremely molten plastic (very liquid, dripping) the first response might be to cool it down with the Fans, however turning on the Fans will make matters a lot worse. Instead, control the state and temperature of the output first using the Heaters.

Error Messages:

There are no sensors connected to the Fans, therefore no Error Messages.

Further Information

Troubleshooting tips concerning a liquid output.

Next essential: The Sensor